- Home

- Knowledge library

- Self-feed and easy-feed silage

Self-feed and easy-feed silage

Find out the advantages and limitations of self-feed and easy-feed silage, how to manage the clamp face, and tops tips for silo management.

Read the full article: Self-feeding silage - the way forward for your farm?

Self-feed and easy-feed silage: what are the differences?

Self-feed silage involves cows eating directly from the forage clamp, usually under the control of a barrier or electric wire set across the face to ensure even feeding.

Easy-feed silage is an adaptation of this system, with silage pulled down from the face and fed behind a barrier set across the clamp. It is usually used with taller silage faces. In an easy-feed system, silage might also be cut from tall clamps and fed in ring feeders to help improve intakes, or for shy feeders and heifers. Beware that self-feed on a high clamp can become compacted, reducing intakes.

Advantages

The main advantage of self-feed and easy-feed silage systems is their simplicity.

No additional machinery is required, and the labour input is confined to resetting the feed barrier or wire and keeping the feeding area clean.

Usually linked with parlour concentrate feeding, such systems are best suited to lower-yielding herds.

Limitations

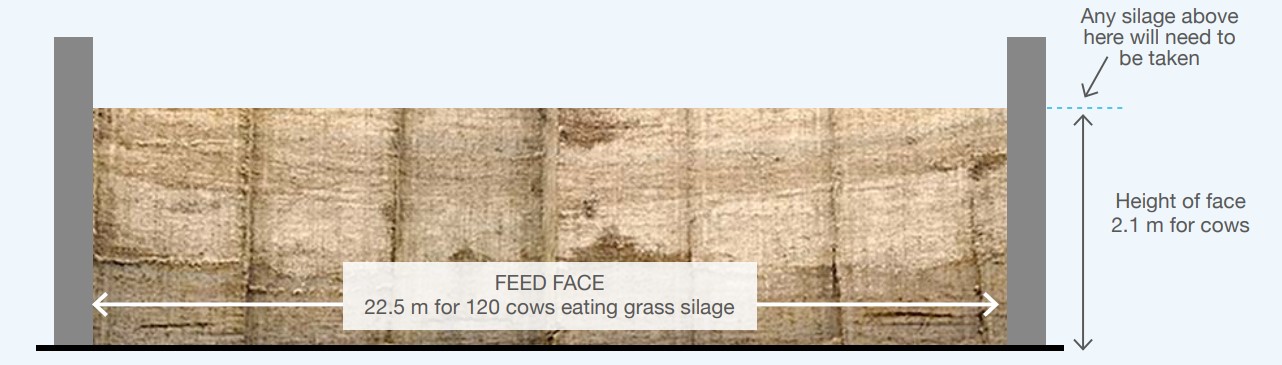

Since cows can only reach a certain height, the depth of silage storage must be kept within this level, or silage above the effective feeding height must be removed mechanically (easy-feed). The silage face must be wide enough to give all cows sufficient access, and the feed barrier reset regularly to avoid restricting dry matter intakes (DMI).

Silage clamps must be close to cow accommodation and constructed to ensure that slurry flows away from the feed face. As cows work their way through the clamp and the face moves back, the area to be scraped gets bigger. This can be fenced off to reduce the scraping area. There is more yard area to be contaminated, which turns rain into dirty water. Therefore, good storage for effluent is needed.

Costs

The capital cost of self-feeding and easy-feeding is generally minimal, being confined to gating and feed barriers or wire. However, the layout of the unit must be carefully planned to ensure good cow movement between silage clamp and cow accommodation. Generally, roofed clamps are valuable to minimise rainwater adding to slurry volumes. The systems allow machinery and labour costs to be kept to a minimum, although they are not suited to high-output businesses.

Top tips for self-feed silage, by consultant Kay Carslaw

Silo management

- The approximate width of feed face per cow with 24-hour access should be 22.5 cm for grass silage only and 17.5 cm for 50:50 grass and maize

- Height of face for cows should be 210 cm (if higher, shear grab grass or pull down maize to this height each morning). For youngstock, aim for 120–180 cm

- Silo width can be any width and, with proper tension and level concrete, extra wire support can be avoided up to about 39 m

- Wide silos can be filled sideways so that some of the silo space can be used twice by starting feeding at 90° from the side until the day maize is harvested. From then on, self-feed both grass and maize from the front in the normal way

Face management

- Use electric tape (narrow), or, preferably, string with sprung handles as the feed barrier so that the barrier can be moved live, with two pairs of screw-in insulators per clamp. The fencer should be on a low power setting

- The height of the barrier should be 80–85 cm for cows and about 75 cm for youngstock. For wider silos, attach the fence at 87.5–92.5 cm

- When youngstock are first being trained to eat over it, you may need to lower the tape (alternate sides) to just below the animal's brisket. All ages of stock should be trained to self-feed over and under the tape just as they can be trained to graze pasture properly

- Ad-lib grass silage feeding for cows is achieved by moving the tape, preferably just once in the afternoon, to 47.5–52.5 cm from the face (for maize 62.5–75 cm). Do not move the tape closer to the face, or there will be overhangs, waste and unnecessary work with no intake benefits

Tidiness

- Cut off the plastic every few days, so it always overhangs the silage by at least 30 cm to shed rain away from the feed face

- Keep one complete row of tyres along the front to hold the sheet down. Use heavy silage covers and gravel bags instead of tyres for the rest of the silo

- Do not try to make cattle self-feed through any water cones in grass silage (caused by rain running in at the sides or through a hole in the top sheet) because they will not do it. Shear or fork the cone down, and then they might

- If any silage needs to be pulled or cut down, do it in the morning, with the wire moved at least 1 m back from the face so that it is all eaten by the time of the regular move forward later in the day

- Fence off empty silo space as it expands during the winter to save scraping. Get a large yard scraper, which scrapes, rather than a small one, which smears. Then get a slurry ramp extension so you can always scrape forwards – this can save up to one-third of your scraping time

Common mistakes

- Fencer power too high

- Barrier wire too low or too close to the feed face

- Insufficient sheet overhang and too many tyres, or sheet removed from near the face too soon

Management of a self-feed silage face

Useful links

Find out more about Forage First

Read our information on silage

Learn more about electric fencing for livestock

Want to visit a self-feeding clamp near you? Find your local dairy knowledge exchange manager

Topics:

Sectors:

Tags: