- Home

- Knowledge library

- Youngstock housing case study – Holly Green Farm

Youngstock housing case study – Holly Green Farm

Neil and Jane Dyson farm with their daughter, Susannah, and son-in-law, Adam, at Holly Green Farm in Bledlow, Buckinghamshire. The 450-cow seasonal calving herd (calving mid-June to mid-November) yields around 9,200 litres (L) of milk per annum.

Around seven years ago, the decision was taken to invest in a new calf-rearing facility to reduce workloads and improve the performance of the heifer calves.

The building in detail

Building specifications

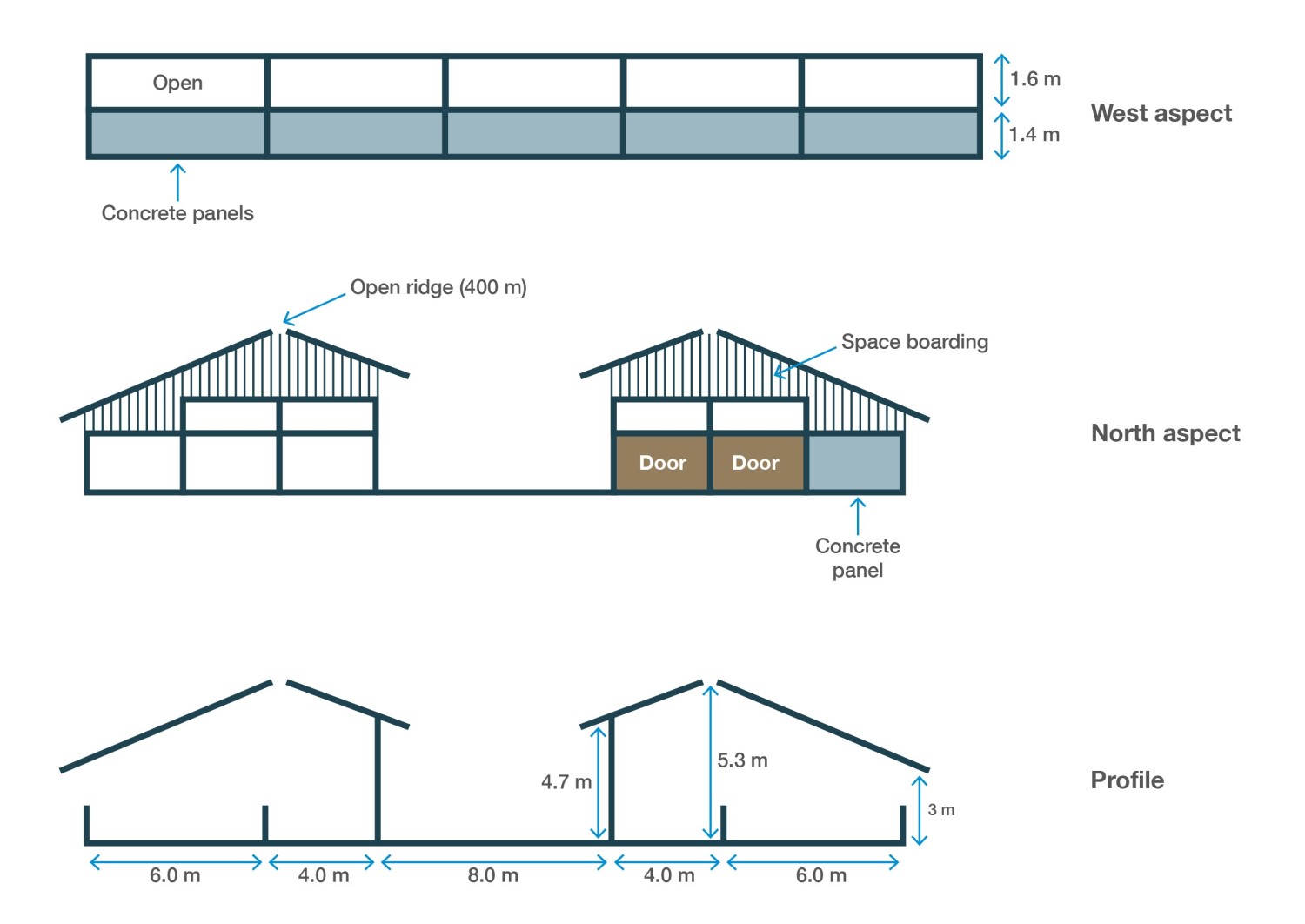

The facility comprises two offset portal frames, facing each other across an open-access passage.

One building is 36 m long, and the other building is 30 m long. Both buildings are 10 m wide, not including the overhang to protect the feed. The buildings are positioned in a north-to-south aspect.

Each building is 3 m high to the eaves on the outside and 4.7 m to the eaves against the open access passage and has a 400 mm open ridge 5.3 m high. The building is surrounded by 1.4 m high pre-cast concrete panels with no cladding from the concrete panel to the eaves.

The buildings can house 132 calves in pens of 12 calves. The 36 m long building can accommodate 72 calves, and the 30 m long building houses 60 calves.

When the 36 m long building is stocked with 72 calves, there is approximately 3.1 m2/calf inlet area and 0.2 m2/calf outlet area through the open ridge.

The north-facing gable ends of the building are a combination of concrete panels, space boarding, two opening gates and clear space above the gates.

The southerly aspect of both buildings is a combination of concrete panels and space boarding, although the calf kitchen and bio-security area reduce the inlet area slightly. Around 10% of the roof area has roof lights. The roof is non-insulated fibre cement.

The roof pitch is 20°, and the building has a 400 mm wide open ridge.

There are no falls on the floor.

Internal layout

The building has been carefully designed to address the issue of large numbers of calves each day, commonly seen with seasonal calving herds.

There are six pens in the 36 m-long building. The straw-bedded pens are 6 m x 6 m and accommodate 12 calves (3 m2/calf). Each pen also has a 6 m x 4 m hard standing against the feed barrier so that each group of 12 calves has access to a total area of 60 m2.

Each pen has a water trough. Concentrate feed and straw are fed along a feed barrier.

The 6 m x 6 m pen is initially divided into two 3 m x 6 m pens with six calves in each. The dividing gate can then be removed to allow the 12 calves to mingle in the larger pen.

The facility has no dedicated isolation pen.

Building blueprints

Blueprints of Holly Green Farm have been drawn up (see below). These have not been produced by architects and have been created by AHDB to reflect the design on the ground. They should not be used as complete plans, and you should always seek the advice of a qualified architect before designing and constructing buildings.

Holly Green Farm aspect

Calf management

Calves are brought to the building as soon as practical after calving, and the calf is placed in the smaller 3.0 m x 6.0 m pen with five other calves.

After two weeks, the pen divider is removed, and the two groups of six calves are allowed to mingle. This group of 12 calves will then stay together in this pen until they are turned out to graze the following summer.

The pens are bedded daily with straw until the calves are weaned, and after weaning, the pens are bedded three times a week.

The pens are cleaned out and re-bedded every six weeks, followed by a thorough cleaning and disinfection once the calves are turned out to graze.

Heifer calves weigh, on average, around 39 kg at birth and achieve a daily weight gain of 800 g/day until weaning.

Calf feeding

All calves receive two 3 L feeds of colostrum in the first 12 hours.

When the calf is in a group of six calves, they will all receive whole pasteurised milk for the first four feeds in a plastic multi-calf feeder, which is hung on the gate.

After four feeds (two days), the calf moves onto powdered milk and will receive two feeds a day of 2 L which increases to two feeds a day of 3 L until week four.

From week four to weaning, the calves are on a single daily feed of 4 L of powdered milk.

When the two groups of six calves are amalgamated at two weeks, the plastic multi-calf feeder is replaced by a 100-L drum feeder with 16 teats. The drum feeder is filled from a mixing milk cart. Powdered milk is prepared in a separate calf kitchen adjacent to the calf buildings.

Between milk feeds, each calf has access to water and ad-lib concentrate feed which is fed in troughs hanging on the gates.

Weaning commences around week eight and is based on the consumption of concentrate feed. Calves need to be consuming a minimum of 1 kg/day of concentrate feed, although 1.5 kg/day is preferable.

Biosecurity

Biosecurity is critical to the success of the calf-rearing facility at Holly Green Farm.

Access to the site is restricted by gates, which are kept closed at all times with clear signs informing people not to enter. While great attention is paid to biosecurity, there is a particular focus on disease control in the period from birth to weaning.

Clearly displayed signs help indicate one-way systems and where access is allowed.

Personnel entry to the site is through a dedicated cabin where staff change into dedicated overalls and boots.

A dedicated shed where dirty boots and overalls are changed for clean boots and overalls before entering the pens.

The multi-calf feeders and milk drum are cleaned with hot soapy water and a brush after every feed, as is the milk mixing cart.

Cleaning and disinfection are based on the ‘all in, all out’ principle. Pens are cleaned out every six weeks through the autumn and winter. Once the calves are turned out in the spring, the whole building is thoroughly cleaned out, all straw removed and deep cleaned.

Cleaning and disinfection are based on two passes through the building with a pressure washer, cleaning all floor surfaces, walls and gates. This is followed by a final pressure wash using a disinfectant and then a period of rest to allow drying before calving commences again in mid-June.

Labour requirements at peak numbers

The farm employs a dedicated calf-rearer for the season. The labour requirements change as the season progresses, being high at the outset when calves are being fed twice daily on multi-feeders in groups of six calves.

In the morning, when calves need a milk feed, milk feeders are cleaned, concentrate topped up and fresh bedding applied. Around 4 hours of labour is required.

In the afternoon, once milk feeding drops to a single daily feed at week four, the labour requirement drops to around 2 hours.

A total of 6 hours per day is required from one person for 132 calves.

Capital cost

The facility cost around £136K. This included the planning fee, site preparation, hardcore, concrete, steelwork and erection, fittings, electrics and water, and the mixing room. The cost did not include any equipment such as a water heater, fridge, or milk mixer.

This equates to around £1,030/calf.

Thoughts on the facility

While the facility works very well, provides flexibility and is relatively easy to manage, there are some potential improvements that may be made in the future.

The efficiency of scale, feeding and managing calves in groups of 12 should not be underestimated.

When inclement weather is driving in from the south-west, the building orientation means that the 36 m long building, which faces west, can suffer from wet straw beds. Some form of cladding on the prevailing weather side of the building is being considered.

The ridge is open and unprotected. While this is potentially helpful in terms of stale air removal, a combination of building height and animal size means that little stack effect is generated.

When rain falls, the area under the open ridge can get quite wet. In the future, consideration may be given to installing a protected open ridge.

Finally, the floors in the shed have been laid flat, which means there is very little natural drainage. The family have said that if the building were to be built again, it would be built with a 5% fall on the bedded areas.

Read more about youngstock housing

Legislation and market requirements

Temperature, humidity and ventilation

Housing layout and construction

Designing housing to feed calves with ease